Donisthorpe Colliery

Mining History Feature

Donisthorpe Colliery

Mining History Feature

Donisthorpe Colliery was near Ashby-De-La-Zouch, Leicestershire in the English Midlands.

I.A.Recordings visited the colliery on 12th April 1990, to make a record of the last steam winding engine still working in the Midlands, only to discover that the mine was Officially due to close at 12 noon, that day!

Background

The mine was first sunk in 1871 by the colliery owners Checkland and Williams to a depth of 205m (672 feet). In 1890 they deepened mine to 263m (863 feet).

Donisthorpe Colliery was originally 2 pits. The current No.1 Shaft was Donisthorpe Lower Pit and No.2 Shaft was Donisthorpe Upper Pit - both were worked by different Mining Companies !

In 1903 the mines came under the control of the newly formed Donisthorpe Colliery Company Ltd. (which later became part of the Moira Colliery Company combine). Over the next sixteen years the new company introduced a number of changes and improvements. These included installing electricity underground to replace steam and oil powered equipment, while on the surface a new generating plant, steel headframes, new winding gear and improved workshop facilities were built. The company also acquired 50 houses for mine employees and employed 90 horses and ponies underground.

As a result of these changes the mine output was tripled to 300,000 tons per annum.

1940 to 1990

A: Main signal board

A: Main signal board

In the 1940's new reserves were being actively sought, in what became the Oakthorpe, South, Newfields and Woodfield sections. To help work these reserves a new pit bottom was constructed.

Following Nationalisation, 1948 to 1952 saw the installation of modern mechanical coal winning equipment and a complete re-organisation of the main underground road transport and winding operations. On the surface the Pit-head baths, Canteen and Medical Centre were built during this period.

In 1951, Donisthorpe won a National Competition for Britain's Best Pit, and during this period broke many Area and National records, with overall output rising to about 750,000 tons per annum. By the mid sixties, output had reached 1,039,018 tons per annum.

In 1966 new workshops, lamproom, rescue room and deputies offices were added to improve surface facilities.

To improve coal handling in 1980 a 2,200m long drift was driven to connect the pit to Rawdon surface. At the same time Donisthorpe pit bottom was reorganised and an 800 tonne vertical bunker installed.

Despite the improvements over the years and the still considerable reserves (22 new faces had recently been created in this mine complex, only one of which had started production) the Mine was deemed uneconomic and scheduled for closure. As all the faces were good and level, with plenty of room the miners could not understand why the pit was being closed!

The majority of the miners at this pit were members of the Union of Democratic Mineworkers, formed during the 1984 Miners Strike.

At the time of closure Donisthorpe was only one of two mines in Britain to still retain and use a steam winding engine (on the Number 2 Pit).

No.2 Pit

Drivers view

Drivers view

Engine: A horizontal twin cylinder (or duplex), steam winder. 28" diameter cylinder with a 48" stroke. Date not known, probably around 1880-90. Working pressure typically 75-80 psi, although the engine was just apable of winding at 65 psi.

The valve gear was of the piston type, with what appeared to be Gooch governors.

Overhauled by J.Jessop, London Steam Crane Co., Leicester in 1916. The original engine plates were brass, but stolen at some stage. Anti-stall valves were attached to back of the cylinders in case of overwinding.

Winder: Worsley Mesnes originally with steam brakes and banking engine, although these were taken out in 1978 and replaced with an electric banker and "Blacks" pneumatic brakes to meet safety requirements. Keps done away with about the same time (ie: disconnected) due to a couple of close winding accidents - winding the cage down against them!

The steam brakes were not entirely effective, due to an uneven winding drum (it was slightly elliptical). Mr. E. Phillipson, one of the last drivers, said that there was a tendency for the old steam brakes to judder and run on. This caused the bottom deck of the down cage to slide into the sump.

However, the cages could be controlled entirely by steam - as Mr. Phillipson demonstrated, stopping, and reversing the cages several times in the shaft during the recording to prove his point.

Winding

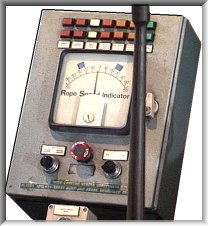

B: Rope Speed Indicator (analogue) & drum revolution indicator dial

Winding was regulated to a maximum rope speed of 29ft. per second. The overspeed devices cut in and shut the steam off, automatically braking the drum to prevent overwind (Mr.Phillipson also demonstrated this!). The engine was actually capable of reaching rope speeds of 40ft. per second.

Methods: To operate the engine, the driver stood on a small wooden platform, with his foot on a foot brake (deadmans type), holding the steam regulator lever (throttle) in his left hand and the reversing lever in his right hand. There were modern additions eg: electric switches to turn on initially to release safety brakes etc.

Signals had to be received from both pit top and pit bottom before winding could commence. "First Man" and "Last Man" were rung from the cage, when there was no Onsetter at pit bottom and the first/last man was descending/ascending.

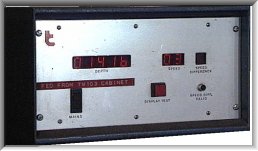

The driver watched a drum revolution counter, (fixed below and to the right of the main signal board, near the crankshaft of the engine) along with a digital rope and depth speed indicator (on a window ledge to his left) - this superseded an old analogue rope speed meter on the drivers control panel in front of him (although this meter still worked).

The drum revolution counter was marked 0-10-10-0. When the pointer approached 0 on the left hand side the driver looked for the left hand markers on the side of the winding drum, similarly for the right hand zero position, thus enabling exact positioning of the cage.

C: Main Drivers Consol, with Banking lights at the top and Overwind clearance button (F) underneath.

When the cage was 3 drum revolutions from the top a bell rang, and the rope speed had to be down to 3ft. per second for the last 3 revolutions - otherwise the overspeed devices were activated.

When tub winding, shifts were split between 2 engine drivers; they worked one hour on, one hour off.

Originally the cage was rated at 5 tons, but re-rated in 1978 at 1.5 tons, winding two double deck cages, maximum of 7 men per cage deck.

When they were using the engine for coal winding, they would typically perform 80-89 winds per hour. However there was one driver who was capable of 96 winds per hour. He would be very annoyed if he didn't achieve this, but would require the "A-team" working the cages!

At the time of closure the engine was painted green. The engine driver considered the engine house to be filthy - as two days before the cable had been re-capped and he had not been on duty to clean up the mess (we couldn't see the dirt!)

The pit rules on the wearing of safety helmets seemed to extend into the Engine house.

Working depth at closure: 227m (746ft.)

(working pressure 65-80psi)

No.1 Pit

Winder: At time of closure an electric winder, working a 300m (~1,000 ft.) shaft. It wound 2, double deck cages and had a top speed of 9m (30ft.) per second.

On inspection runs, the winder ran down with men on the top of the cage at 0.7m (2-3 ft.) per second, but up at 9m (30ft.) per second. The shaft inspector doubled up as the boilerman!

The original pit bottom was at 183m (600 ft.), where pony stables were located. Until 1978 some time sheets dating from 1924-26 were still there, these were found at the time the electric winder was installed - replacing a steam winder (horizontal twin cylinder [or duplex], rebuilt by Worsley Mesnes Ironworks, Wigan 1915/16, 26" x 54", possibly dating from 1880's - removed to the NCB's National Mining Museum, Lound Hall in 1978. (This musuem closed in 1989, the engine may now be at Caphouse Colliery, or scrapped).

No.2 Pit Bank

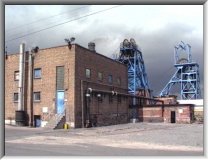

Bankside Buildings: The buildings date from 1919, although the headframe was 1942.

Fan taken out of commission about 1978/80 - this was the Upcast shaft.

Boilers: Steam was provided by one of four Lancashire type boilers with mechanical chain grate stokers, coal hopper fed from above, ash fell onto another chain conveyor to be removed from the boiler, where it fell down a chute onto a conveyor running along the front of the boilers (under the floor). From here it was conveyed out to the end of the boiler complex, and discharged into an old mine tub for disposal.

The boilers were only covered at the firing end - the cover building actually being the coal hopper. The boilers were on brick supports, open to the elements, but lagged, at the top. At the rear of the boilers were the Superheater boxes, behind them the Chimney.

General

Coal was originally brought to bank in tubs, emptied via a tippler on the top platform of the bank onto a conveyor and taken to the screens. The screens building survived as a store, but the conveyor was dismantled in the 1960's - when this pit stopped winding coal. Only supplies and men were still wound at Donisthorpe, all coal came out via Oakthorpe - connected underground along with several other local pits, some of which had closed at the time of the visit. Donisthorpe Colliery was situated at NGR SK 313 143

Acknowledgements

The authors of this item would like to thank Mr.E.Phillipson for kindly operating the engine and explaining it's operation; Mr. M.W.Gardner (Banksman), and all the Men at Donisthorpe Colliery who took the time to talk to us, both on the surface and underground.

Thanks to Stuart Warburton of Leicestershire Museums Service, who arranged the visit to the Colliery (the engine is now in storage at Snibston Museum).

Authors: A.J.Mugridge & Kelvin Lake

The images on this page are taken from Compilation C.18 - "Donisthorpe Colliery".